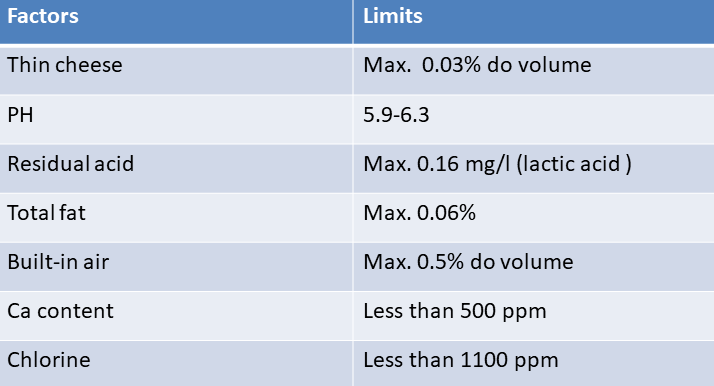

The following parameters are considered for the preliminary study of the treatment options presented here:

Semi serum demineralization - Nanofiltration

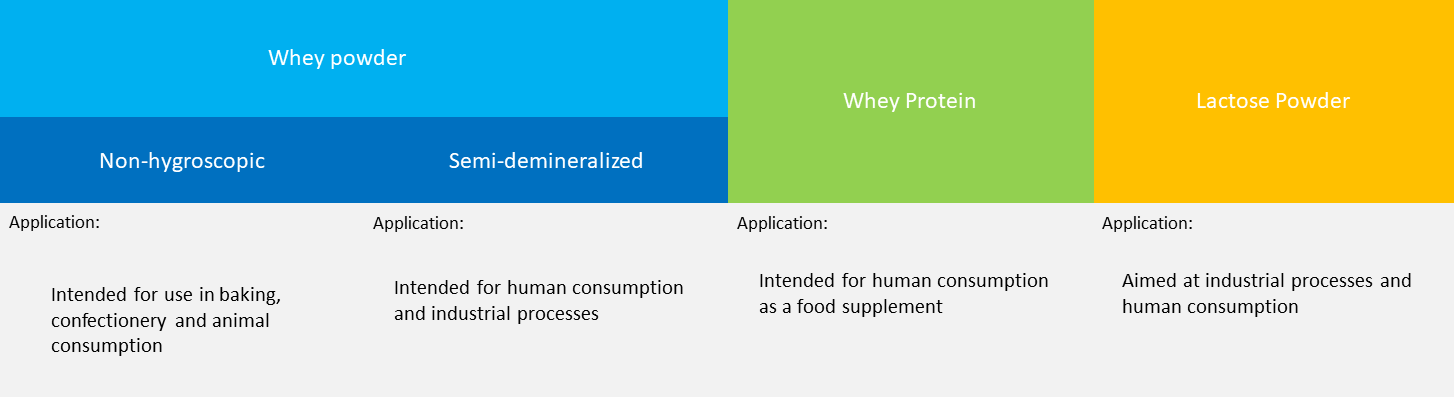

This system is intended for the production of semi-demineralized semi-hygroscopic serum, using Nanofiltration technology to remove salts with dimensions of approximately 0.001 mm, reaching reductions of up to 50% in the salt content at the product entrance, generating the concentrate and the permeate. All the retentate can be sent to the concentration or the ultrafiltration equipment for WPC production and all the permeate can be sent to the reverse osmosis equipment, where the residual solids will be removed and it is possible to use the permeate industrial applications.

Protein Concentration (WPC) - Ultrafiltration

This system is intended for the production of semi-demineralized non-hygroscopic serum whey protein (WPC) from a concentrate from Nanofiltration. As it is known, milk contains several types of proteins, among them, Casein and proteins from the membranes of fat globules - Whey Protein (also called Lactoalbumin).

Whey is obtained after the extraction of casein from milk (in the manufacture of cheeses, for example) by addition of acid medium (acid serum) or addition of enzymes (sweet whey). Thus, any 18% whey concentrate from semi-demineralization (nanofiltration) can be sent to ultrafiltration to increase the serum protein concentration to 24%. This concentrated (retentate) concentrate in the ultrafiltration will be sent to intermediate storage from where it will be transferred to the concentration, where the correction of the total solids content will occur, and later, to crystallization tanks to regularize the structure and to dry to obtain WPC 35 no hygroscope.

The permeate (basically lactose) will follow a flow similar to the concentrate described above, to obtain lactose powder.

Permeate Treatment - Reverse Osmosis

This system is intended for the removal of solids from the permeate from the Nanofiltration, for the purpose of use in the industrial process of the plant.This processed permeate can be directed to the water reservoir or the water treatment area for boilers, providing volume reduction of daily water, and the concentrate will be directed to Expedition.